What is a PLC and why should I use one?

There is a persistent problem I’ve been coming across in my career. Which is that people don’t know what PLCs are or what they do or why should they use one?

The way it seems to work, is that some entity has a great idea and wants to build a machine, or mechanical system of some sort. The first thing they do is hire a mechanical engineer, because obviously to build a mechanical system you need a mechanical engineer.

The mechanical engineer does their job and designs and builds a system and it’s GREAT! Management comes and says: OK, now turn it on. The mechanical engineer goes, uhhhh… that’s not my job. Well, I guess we better get some “software guy” to “program it”.

They find some “software guy” that knows how to use <insert programming language, operating system here>. Then they cobble together a maze of operating systems and servers and interface devices with communication protocols and programming languages and all the stuff. It becomes hopelessly convoluted and the only person that can possibly unscramble it is the original software guy that put it together (if you’re lucky). Now the system sort of works, but the mechanical engineer has no idea how the control system works, and software guy has no idea how machines work. So that if anything doesn’t work quite right, everyone blames everyone else, and the whole project goes sideways.

This whole situation could have been avoided if they hired an experienced controls engineer to design the control system based around a standard PLC platform.

So what is a PLC?

PLC stands for Programmable Logic Controller.

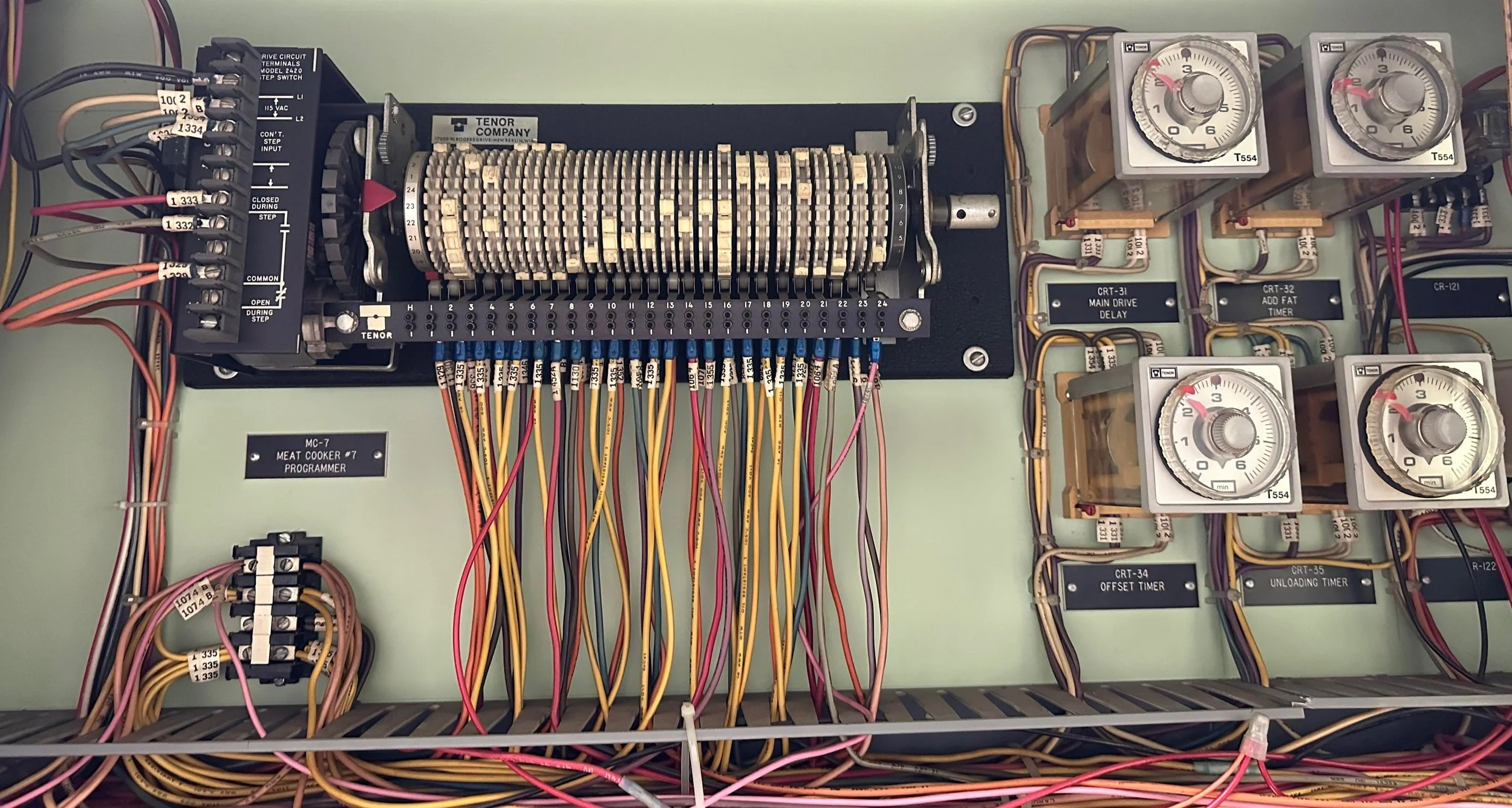

PLCs were developed in the late 60’s to replace hardwired solenoid relays being used to do rudimentary logic and sequencing. The most common programming language is Ladder Logic, which is directly based on how electrical schematics are drawn. If you can read an electrical schematic, you can understand Ladder Logic.

PLCs typically have a Graphic User Interface, commonly abbreviated as an HMI, Human Machine Interface. The graphic elements on a typical HMI platform are mimicking the physical lights and buttons that would be installed on an electrical control panel.

A typical PLC has a processor, an assortment of input and output cards or modules, communication modules, and specialty modules such as Pulse Width Modulation or High Speed Counters. Importantly, the IO is integral to the PLC operating/programming environment, and not a discrete 3rd party device.

Each brand of PLC has it’s own programming software and user environment. They’re all similar, and if you know one, you can learn another. The major brand in the USA is Allen Bradley. Siemens is the major player in Europe.

Today, all the major brands adhere to the IEC 61131-3 standard, which specifies 5 different programming languages. In practice, in addition to Ladder Logic, the most commonly used language is Structured Text, which is text based and similar to Pascal or BASIC. Again, if you understand one brand of controller, you can very quickly learn another brand.

At no point in my career have I ever encountered a machine control problem where I was unable to solve it using the standard languages within the PLC and felt the need for a different programming language.

A PLC is designed to control machinery. That’s it.

There is NO OPERATING SYSTEM as one would expect on a PC. It has a real time operating firmware with deterministic communication protocols. There is no Windows to update, or crash. There is no internet. It is a stand alone hardware device that is programmed to control machinery, period. You turn it on, and it works.

Industrial machinery must follow industrial wiring protocols, and all that entails. This means the control system is either 24vdc or 120vac. Everything has industrial rated terminals. And all the components are industrial rated with the appropriate certifications such as UL. 5vdc electronics with pin connectors are not appropriate for an industrial environment.

Industrial systems must follow industrial safety requirements, and include things such as E-Stops, light curtains, and safety relays. PLCs have been tested and rated and qualified to meet industrial standards.

The code execution on a PLC is deterministic. The simplified meaning is that everything is based on a scan time, if something hangs up it causes a fault and it stops in a safe condition. The same can be said for the communication protocol, Ethernet/IP. Non-industrial protocols are not deterministic. An Ethernet TCP/IP command can get sent to a device, and get “lost”, without faulting out. This time or cycle based operation is critical in an industrial application.

Will <trendy programming language> running on a laptop fault out in a safe manner if something doesn’t work right? If something doesn’t load, or update, could the machine it’s controlling seriously injure someone?

Or maybe the OS decides to update itself? Or maybe a service tech was using it to browse the web and got a virus? Or maybe a cable was disconnected, and the logic didn’t fault out, and when it’s reconnected, the machine has an “unexpected motion” event?

Will you trust your project with your life? Not metaphorically, but literal grievous bodily harm, death.

This is exactly the point. PLCs are designed to operate machinery that can kill you.

I’ll keep going. Active product lifespan.

The humble AB Compactlogix PLC has a guaranteed active product lifespan of 20+ years.

20 years from now, I can go to a OEM vendor and buy the same components brand new off the shelf. And the software includes all the legacy versions, so I will still be able to program it as it was done originally. There are AB machines in the field that are still running PLCs from the 1980’s.

With any sort of PC based system, you are at the mercy of the OS. Maintaining legacy systems running obsolete operating systems is problematic, to say the least. In 25 years will we still be able to update a system running on Windows XP? Was your current service technician even alive when Windows 95 was a thing?

A well built system running a PLC controller, can last 20, 30 + years, essentially forever.

Contact us:

For all business inquiries please fill out the form below.